Introduction

With the rapid development of new energy vehicles and intelligent cars, automotive electronic systems are placing higher demands on power devices. As a high-performance power semiconductor, the Insulated Gate Bipolar Transistor (IGBT) has become an indispensable component in modern automotive electronics due to its ability to handle high voltage, high current, and low power loss.

Main Applications of IGBT in Automotive Electronics

- Electric Vehicle Drive Systems

- IGBT is the core device in motor drive inverters, converting DC power from the battery into AC power to drive the motor.

- Its high efficiency and fast switching capability improve both the driving range and power performance of electric vehicles.

- On-Board Charging System (OBC)

- In on-board chargers, IGBT enables efficient power conversion, ensuring batteries are charged safely and quickly.

- It also supports bidirectional charging, making vehicle-to-grid (V2G) interaction possible.

- DC/DC Converters

- IGBT plays a key role in converting high-voltage power into lower voltages, providing stable power supply for vehicle electronics such as control systems, lighting, and infotainment.

- Electric Air Conditioning and Auxiliary Systems

- Electric compressors, heating systems, and other auxiliary devices increasingly rely on high-efficiency power components.

- IGBT improves system performance while reducing energy consumption.

Advantages of IGBT in Automotive Electronics

- High Efficiency: Low switching losses reduce overall system energy consumption.

- High Reliability: Performs well under high temperature, high voltage, and harsh automotive environments.

- High Power Density: Supports compact and lightweight automotive system designs.

- Long Lifespan: Ensures durable and stable operation over the vehicle’s lifetime.

Future Development Trends

- Synergy of SiC and IGBT

- While SiC devices excel in high-frequency and high-temperature applications, IGBT remains dominant in high-voltage and high-current scenarios.

- The two will complement each other in EV systems, further improving powertrain efficiency.

- Modularization and Integration

- IGBT modules are evolving toward higher power density and more compact designs, enabling greater performance within limited space.

- Automotive-Grade Reliability Standards

- With rising safety requirements, IGBT design, manufacturing, and testing are increasingly aligned with stricter automotive-grade standards.

Conclusion

As a core power device in automotive electronics, IGBT is driving the rapid growth of new energy and intelligent vehicles. With the ongoing trends of electrification and intelligence, IGBT will continue to play a crucial role in the future of automotive electronics, providing solid support for green mobility and sustainable energy development.

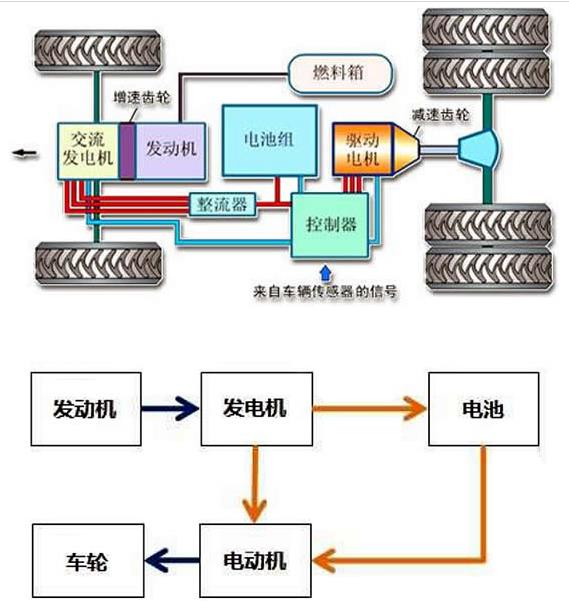

The primary structural components of an electric vehicle can be summarized as follows, as shown in the diagram:

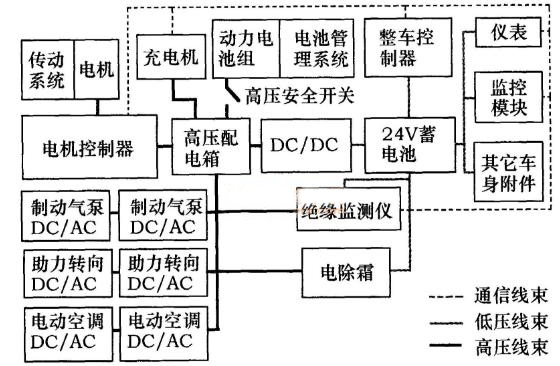

Details of each functional module are as follows:

Our company’s products are primarily applied in the motor, DC/AC conversion, and DC/DC conversion sections.