Under the dual impetus of the reshaping of the global industrial competition landscape and the “carbon neutrality” strategy, the wave of domestic substitution for power semiconductors has become unstoppable. For downstream application enterprises, this is not merely a “backup plan” for the supply chain, but a precious opportunity to comprehensively enhance product competitiveness and achieve technological autonomy.

1. Strategic Foundation: Building a Secure and Resilient Supply Chain

In today’s era of global challenges, supply chain security has become the lifeline of enterprises.

- Break the monopoly and gain the initiative: Long-term reliance on a single overseas supplier means handing over one’s own technological route and production lifeline to others. Domestic substitution enables Chinese manufacturers to break free from external constraints and ensure stable supply of core components when facing market fluctuations, geopolitical issues, or trade disputes, thus gaining strategic initiative in development.

- Establish an independently controllable industrial ecosystem: By supporting the domestic power semiconductor industry, China is building a complete industrial chain loop from design, manufacturing, packaging to application. This not only reduces the overall dependence on the outside world but also guarantees the continuous and stable operation of key industries such as new energy vehicles, new energy power generation, and industrial automation in critical moments of the national economy.

2. Performance and Value: The “Double Excellence” Answer of the Domestic Solution

Many people once had doubts about the performance of domestic components, but leading domestic manufacturers have demonstrated their outstanding value through their product capabilities.

Technical compatibility: Deep customization, rapid response, local suppliers can closely cooperate with customers and optimize the design and rapidly iterate the chips for specific application scenarios in China (such as complex power grid environments, high-temperature and high-humidity climates), achieving “tailor-made” solutions.

Cost optimization: Significant cost advantages throughout the entire lifecycle. Besides more competitive purchase prices, local supply also significantly reduces hidden costs such as logistics, tariffs, and fluctuations in exchange rates, and provides more economical and efficient technical support and services.

Service and support: Personalized service, joint development, can provide rapid technical responses 24/7, from chip selection, circuit design to fault analysis, providing in-depth support throughout the entire process, helping customers shorten the product launch cycle and solve “critical technology” problems.

3. Collaborative Innovation: The Catalyst from “Substitution” to “Leadership”

The deeper advantage of domestic substitution lies in the collaborative innovation effect it triggers, which is transforming the cooperation model of the industrial chain.

- Driving the exploration of technological frontiers in application fields: When chip suppliers, vehicle manufacturers, and inverter manufacturers sit together to jointly develop, it leads to system-level innovations. For instance, in the field of new energy vehicles, in response to cutting-edge directions such as the 800V high-voltage platform, the mixed application of SiC (silicon carbide) and IGBT, a closely-knit “chip-module-system” joint research and development team has been formed in China.

- Accelerating the implementation of next-generation technologies: As silicon-based IGBT becomes increasingly mature, third-generation wide-bandgap semiconductors represented by SiC and GaN have become a new global competitive frontier. The close collaboration among the upstream and downstream of the domestic industrial chain is driving new technologies such as SiC to be applied on a large scale in the fields of photovoltaics and electric vehicles at a faster speed and with lower costs, helping Chinese enterprises seize the initiative in the competition of next-generation technologies.

3. Collaborative Innovation: The Catalyst from “Substitution” to “Leadership”

Choosing domestic power semiconductors is not only a strategic decision that combines economic benefits with social value, but also a wise choice.

1: The core support for achieving the “carbon neutrality” goal: Domestic power semiconductors are the key physical foundation for enhancing the energy efficiency of new energy vehicles, improving the efficiency of photovoltaic/wind power generation, and realizing industrial energy-saving renovations. Supporting their development is directly contributing to China’s green energy transformation and carbon neutrality goals.

2: Empowering high-quality development of the manufacturing industry: High-performance and highly reliable domestic chips are the core components for upgrading high-end equipment, intelligent manufacturing, robots, etc. The level of their domestication directly determines the speed and height at which China’s manufacturing industry climbs to the high end of the value chain.

Conclusion

The domestication and substitution of power semiconductors go far beyond merely addressing the issue of “availability”. It is a comprehensive project that enhances supply chain resilience, optimizes product value, stimulates industrial collaborative innovation, and is also in line with national development strategies. For forward-thinking enterprises, actively embracing and deeply participating in this process is not only a wise move for risk management, but also a key strategic layout to build future core competitiveness.

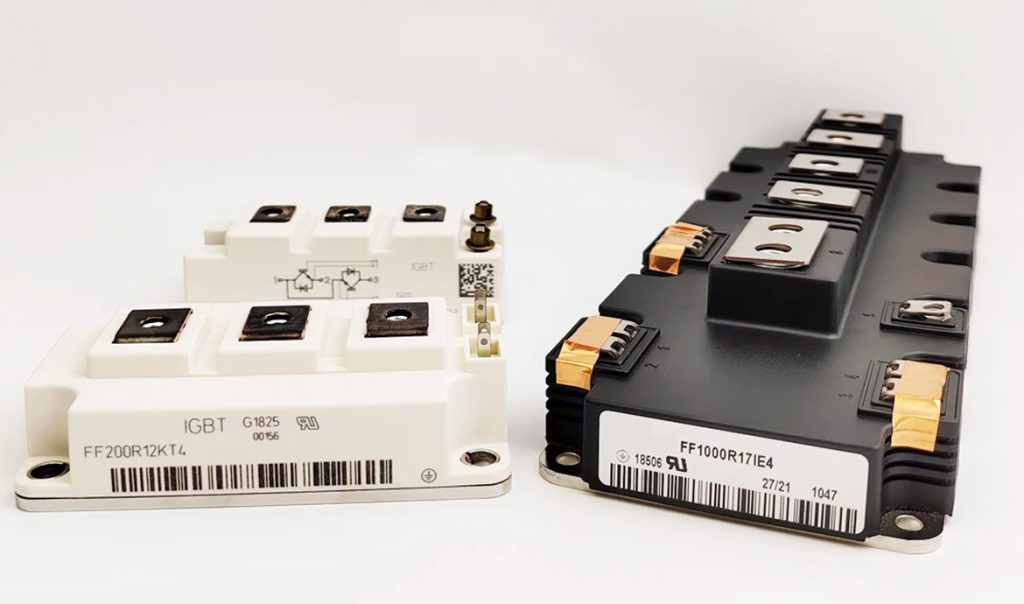

Regarding Linsen Semiconductor, as a national-level high-tech enterprise that has been deeply engaged in the power semiconductor field for over a decade, Linson Semiconductor has always been committed to the research and development and industrialization of advanced chip technologies such as IGBT. With the trench gate field termination technology as the core, we provide high-performance and highly reliable domestic chip solutions, offering a solid technical foundation and comprehensive services for partners’ journey towards domestic substitution, and jointly driving the vigorous future of China’s intelligent manufacturing.