November 15, 2025, China – As the “CPU” of power electronics, IGBTs (Insulated Gate Bipolar Transistors) are driving the transformation of new energy, industrial control, rail transportation and other fields at an astonishing speed. new energy, industrial control, rail transportation and other fields. According to the latest market data, China’s IGBT market size is expected to exceed 24.49 billion yuan in 2025, the global share of more than 40%, the localization rate increased to 40%, marking China’s entry into a new stage in the global power semiconductor competition.

Technological breakthroughs: from “running with” to “running with”

In recent years, domestic IGBT technology to achieve multi-dimensional breakthroughs:

High-voltage high-current field: China Car Times Electric, TBEA and other enterprises have successfully developed 5kA-class crimped IGBT devices, breaking the bottleneck of the capacity of flexible direct transmission, applied to the State Grid Zangdong-Guangdong DC project, to solve the problem of heat dissipation of high-altitude area equipment.

Vehicle-grade applications: Star semi-conductor, Silan Micro and other companies have passed AEC-Q100 certification, supporting more than a million new energy vehicles, the seventh generation of IGBT chips against the international first-class level, the on-state voltage reduced to 1.55V, efficiency increased by 10%.

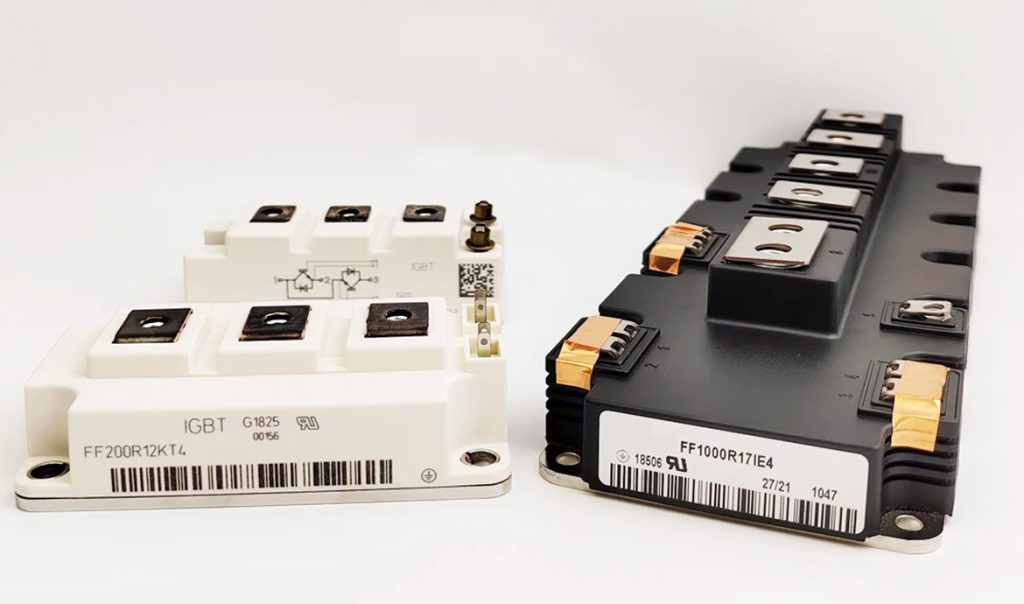

Packaging innovation: SAICING Asia Pacific has launched a low thermal resistance packaging structure, optimizing heat dissipation through epoxy resin-based composite layers, significantly improving the reliability of power modules, and making them suitable for energy storage, three-level inverters, and other scenarios.

Market explosion: new energy drive demand surge

New Energy Vehicles: the number of IGBTs used in a single vehicle exceeds 100, and the cost of charging piles accounts for 20%. 2025 China’s new energy vehicle sales are expected to exceed 15 million, leading to a doubling of IGBT demand.

Wind, light and storage field: offshore wind power converter using 2300V grade IGBT, power density increased by 38%; photovoltaic inverter efficiency breaks through 99%, every 3 sets of equipment in the world will be 1 set using domestic IGBT.

Emerging track: humanoid robot joint drive, electric vertical take-off and landing aircraft (eVTOL) power system and other scenarios, the IGBT puts forward ” Small volume, high response, long range” new requirements for IGBT, promoting the evolution of technology to miniaturization, high frequency

Challenges and opportunities: localization into the deep water

Despite the remarkable progress, the industry is still facing three major challenges:

High-end chips rely on imports: 12-inch wafers, photoresists and other raw materials, as well as DUV lithography and other equipment are still monopolized by international giants, restricting capacity expansion.

Reliability verification cycle is long: automotive-grade IGBT requires 2 years of introduction cycle, offshore wind power equipment requires more than 5 years of testing, failure rate control is still the key.

Cost competition pressure: 8-inch production line costs need to drop 30%, SiC hybrid integration technology needs to further reduce losses, in order to cope with international manufacturers price war.

Future outlook: SiC integration and globalization

The industry is focusing on two major directions:

Technology upgrade: SiC/IGBT hybrid modules will reduce losses by another 50%, and the junction temperature breaks through 200 ℃ to meet the needs of high-temperature, high-frequency scenarios.

Ecological construction: head enterprises integrate the industry chain through IDM mode, midstream manufacturers plowing green power, industrial control segments, emerging forces to packaging innovation to enter the market.

With the promotion of the “dual carbon” strategy, IGBT has become the core engine of the energy revolution. From onshore wind power to deep-sea energy storage, from smart factories to low-altitude economy, this “small chip” is prying trillions of dollars of market, writing a new chapter of China’s high-end manufacturing.