In a landmark move within the global semiconductor landscape, Infineon Technologies AG, a leading semiconductor company headquartered in Neubiberg, Germany, and renowned for its prowess in power systems and the Internet of Things (IoT), has joined forces with ROHM Semiconductor, a well – established semiconductor manufacturer based in Kyoto, Japan. The two industry giants have signed a memorandum of understanding to establish a collaborative mechanism for SiC (Silicon Carbide) power device packaging.

Collaboration Scope and Objectives

The partnership is centered around developing SiC power device packaging solutions for a diverse range of applications, including on – board chargers for electric vehicles, solar power generation systems, energy storage systems, and AI data centers. One of the key goals of this collaboration is to position each other as the second supplier for specific SiC power device packaging types. This strategic move is set to revolutionize the market by enabling customers to source compatible – packaged products from both ROHM and Infineon.

For end – users, this means unprecedented flexibility in meeting various application requirements. Whether it’s a specific design need or the ability to seamlessly switch between products, the partnership promises to enhance the overall customer experience. In terms of design and procurement, the collaboration will significantly streamline processes, making it easier for engineers and buyers to navigate the semiconductor market.

Technological Advancements

Infineon’s Innovative SiC Top – Cooling Platform

As part of this partnership, ROHM will adopt Infineon’s cutting – edge SiC top – cooling platform. This platform encompasses several packaging options, namely TOLT, D – DPAK, Q – DPAK, Q – DPAK Dual, and H – DPAK. A standout feature of this platform is its standardized height of 2.3mm across all packaging types. This standardization brings about a host of benefits. It simplifies the design process for engineers, reducing the complexity associated with integrating different components. Additionally, it helps in cutting down the costs of the cooling system, as a more uniform design allows for more efficient heat dissipation strategies. Moreover, the standardized height enables better utilization of the substrate space, leading to a potential power density increase of up to two times.

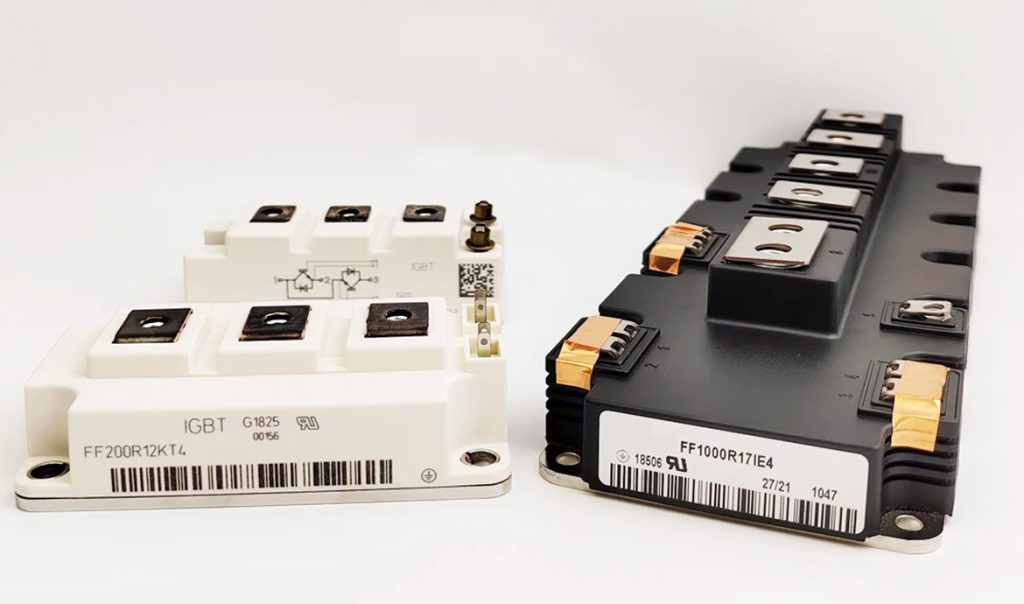

ROHM’s DOT – 247 SiC Module and Infineon’s Integration

On the other hand, Infineon will incorporate ROHM’s advanced half – bridge structure SiC module, the “DOT – 247,” and develop a compatible packaging solution. This integration will expand Infineon’s new Double TO – 247 IGBT product portfolio to include SiC half – bridge solutions. The DOT – 247 packaging from ROHM offers several advantages over traditional discrete device packaging. It features a unique structure that connects two TO – 247 packages. This design results in a remarkable reduction in thermal resistance by approximately 15% and electrical inductance by 50% compared to the standard TO – 247 packaging. As a result, the power density of the DOT – 247 packaging reaches 2.3 times that of the traditional TO – 247 packaging, providing engineers with greater design freedom and the ability to achieve higher power output in a more compact form factor.

Future Expansion and Industry Impact

Looking ahead, Infineon and ROHM have ambitious plans to extend their cooperation beyond silicon – based packaging. They aim to broaden their collaborative efforts into various packaging areas, including SiC and GaN (Gallium Nitride). This expansion will not only deepen the existing partnership between the two companies but also offer customers an even wider array of solutions and procurement options.

In the highly competitive semiconductor market, this partnership between Infineon and ROHM is poised to set new standards. By combining their technological expertise and market reach, they are well – positioned to drive innovation in SiC power device packaging and provide customers with cutting – edge solutions that meet the evolving demands of modern applications. As the industry continues to move towards higher efficiency, compactness, and performance, this collaboration could very well be a game – changer.