In the field of industrial automation, servo drives and communication power supplies, it has always been a challenge for engineers to strike a perfect balance between high power density, high efficiency and high reliability. Recently, Infineon, a leader in power systems and IoT, has introduced its new generation of PSU (power supply) IIP (integrated power protection and interface) modules, which provide a benchmark solution to this challenge with its disruptive and integrated design.

I. Core highlights: Why is it a “game changer”?

Infineon’s new generation of PSU IIP modules is not a simple component upgrade, but a system-level integration innovation. Its core advantages can be summarized in the following three points:

Extremely high level of integration and significant size reduction: The module integrates power factor correction, LLC resonant converter, DC-DC step-down converter, current and voltage sensing, driver circuitry, and a wealth of protection functions, all in a compact package.

Interpretation: This high degree of integration eliminates the need for engineers to perform tedious selection, layout and debugging for dozens of discrete components, greatly simplifying the design process and shortening time-to-market.

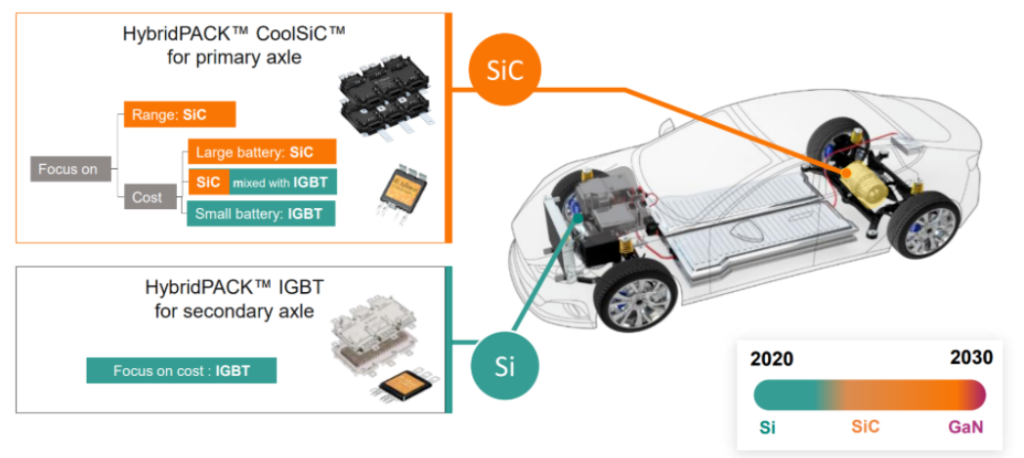

Superior Efficiency for Lower Energy Loss: The modules use Infineon’s advanced CoolMOS™ SJ MOSFETs and SiC diodes to achieve full topology optimization from PFC to LLC.

Interpretation: This means that under typical industrial loads, the entire power supply system is able to maintain extremely high conversion efficiency, which not only reduces energy waste, but also lowers heat dissipation requirements, allowing end devices to run more energy efficiently and cooler.

Rock-solid protection: The modules are fully integrated with over-voltage, under-voltage, over-current, over-temperature and short-circuit protection.

Explanation: This is critical for industrial equipment that requires 7×24 operation. The built-in “Safety Guard” ensures that the power supply system automatically protects itself from abnormal conditions, significantly improving the reliability and service life of the final product.

2.Technology Dive: Uncovering the underlying technology of its high performance

The article analyzes the technical cornerstones that make up the outstanding performance of the PSU IIP module:

PFC Stage: Adopting a staggered parallel totem pole bridgeless PFC topology with CoolMOS™, the module achieves a conversion efficiency of up to 99%.

LLC Stage: As the core of DC-DC conversion, the LLC resonant converter also uses CoolMOS™ and SiC diodes in key positions to optimize switching performance, reduce reverse recovery loss, and further improve efficiency.

Control and drive: The module has an internal integrated digital controller and high-voltage driver for precise power management and control.

3.Application Scenarios: What areas can it revolutionize?

The module’s powerful performance makes it shine in a number of demanding areas:

Industrial servo drives and PLCs: Compact size is ideal for space-constrained in-cabinet installations.

Communication and server power supplies: High efficiency to meet the extreme energy consumption requirements of data centers.

High-end consumer power supplies: such as game consoles, workstations and other products that have a need for high-power, small volume adapters.

4.Engineer’s Value: From “Design and Manufacture” to “Function Realization”

Infineon has brought fundamental changes to power engineers through PSU IIP modules:

Simplify design: Transform complex power, analog and logic circuit designs into simple module selection and interface applications.

Reduce Risk: Pre-integrated and tested modules reduce the number of design iterations and potential points of failure.

Accelerated time-to-market: Engineers can accelerate the development process by focusing more on the core functionality and competitive differentiation of the product.