I. IGBT technology overview

- IGBT (Insulated Gate Bipolar Transistor, Insulated Gate Bipolar Transistor) is a composite fully-controlled power semiconductor device, combining the high input impedance of the MOSFET (Metal Oxide Semiconductor Field Effect Transistor) and easy to drive the characteristics of the BJT (bipolar transistor), and the advantages of the low on-state voltage drop and high current-carrying capacity. BJT (bipolar transistor) with low on-state voltage drop and high current-carrying capacity. The core structure consists of a MOS gate-controlled PNP bipolar transistor, which physically consists of a gate, a collector and an emitter. The gate is isolated from the channel area by a thin oxide layer, forming a voltage-driven characteristics, both high efficiency control and low power consumption advantages

2. Principle and Mechanism of Operation

Conduction Mechanism

- When the forward voltage applied to the gate exceeds the threshold, an inverse layer channel is formed below the P-type base region, connecting the N⁺ emitter region with the N-drift region. The injection of electrons into the N-drift region triggers the injection of minority carriers (holes) into this region from the P⁺ collector region, producing a conductance modulation effect. This process significantly reduces the on-resistance, enabling the IGBT to maintain a low saturation voltage drop (Vce(sat)) under high voltage conditions (hundreds to thousands of volts), improving energy efficiency.

Shutdown Mechanism

- When shutdown occurs, the gate voltage drops to zero or negative, the reverse-type layer disappears, and the current path is cut off. However, because the minority carriers stored in the body take time to compound, a trailing current is generated, resulting in increased turn-off delay and dynamic losses. This characteristic becomes a major bottleneck in high-frequency applications.

Optimization Technologies

- Modern high-performance IGBTs reduce turn-off time and losses through the following technologies:

- Field Stop (FS) structure: Optimizes the electric field distribution in the drift region and reduces the turn-off voltage overshoot.

Transparent collector design: Reduces carrier storage time and accelerates the compounding process. - Enhanced carrier life control process: regulating carrier life through ion implantation or irradiation technology, balancing on and off performance.

3. The drive and control requirements

IGBT operating state by the gate voltage is precisely regulated:

- On stage: the drive circuit provides +15V gate voltage, the establishment of the conductive channel, triggering the bipolar transistor conduction. At this point, the conductance modulation effect takes effect, maintaining a low Vce (sat).

- Shutdown phase: -5 to -10V negative bias is applied to the gate to accelerate channel closure and suppress the risk of false conduction. However, the minority carrier storage effect still causes shutdown delay, which needs to be mitigated by design optimization.

4. Application Scenarios and Advantages

IGBTs have become the core devices of power electronic systems by virtue of their high-voltage, high-current handling capability and thermal stability, and are mainly used in the following fields:

New Energy Power Generation

- Wind Converter and PV Inverter: As the core component of DC/AC converter, they support the three-phase PWM rectifier and inverter topology to realize high-efficiency power quality regulation.

- Typical voltage level: 600-1200V, suitable for high power density requirements.

Electric Vehicles and Rail Transportation

- Traction Inverter: Highly efficient conversion of battery DC power to AC motor power supply, with regenerative braking support.

- Advantage: Wide speed range and fast dynamic response to meet the harsh working conditions of rail transportation and electric vehicles.

Industrial Drive Equipment

- General-purpose inverter and servo drive: motor speed regulation is realized through IGBT, combining high-precision control and energy-saving effect.

- Application scenarios: CNC machine tools, industrial robots and other equipment requiring a wide speed regulation range.

Household appliances

- High-end air conditioners and washing machines: Built-in IPM (Intelligent Power Module) modules and integrated IGBT units to realize vector control, improving energy efficiency and operational stability.

Smart Grid Infrastructure

- Flexible power transmission and distribution devices (e.g. STATCOM, UPFC): IGBT-based multilevel converter valve body supports reactive power compensation and trend scheduling to enhance grid stability.

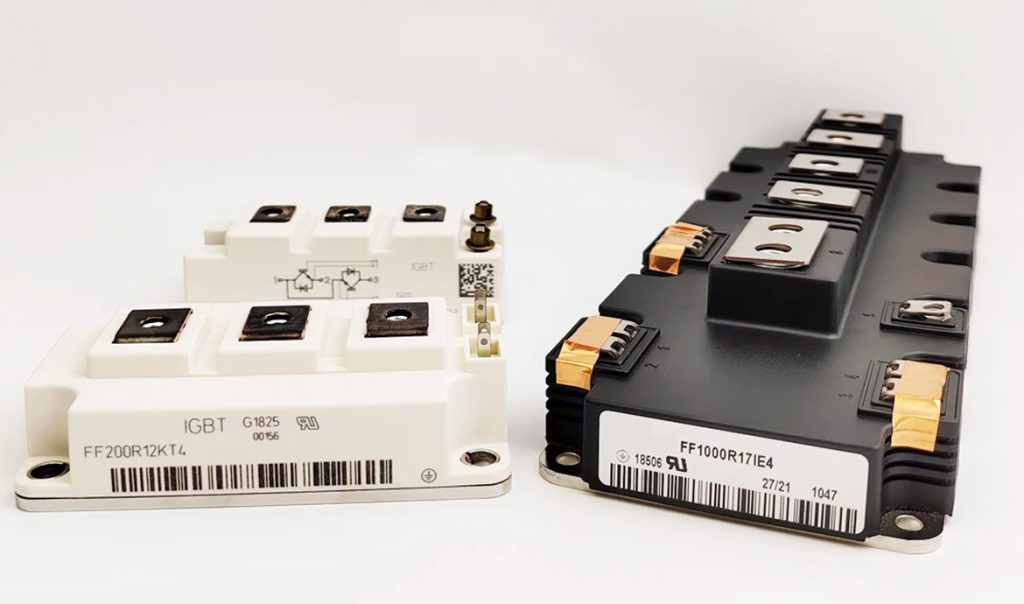

5. Technology Evolution and Product Classification

In response to the needs of different working conditions, IGBT technology continues to iterate, forming a diversified product system:

- Planar IGBT: Early structure, simple process but limited performance.

- Trench-type IGBTs: trench gate structure to improve current density and reduce conduction loss.

- Field cut-off IGBT: Optimize electric field distribution by using field cut-off layer to improve turn-off speed.

- RC-IGBT (reverse conduction type): integrated reverse shunt diode, simplify circuit design, suitable for high frequency applications.

6. Summary

- IGBT as the “heart” of the power electronic system, through the integration of MOSFET and BJT advantages, to achieve a balance of high voltage, high current and efficient control. Its working mechanism relies on the precise regulation of the gate voltage on the channel state, while the minority carrier storage effect in the shutdown process needs to be mitigated through structural optimization and process innovation. IGBT has become an irreplaceable core device in the fields of new energy, electric vehicles, industrial drives and smart grids, promoting power electronics technology to develop in the direction of high efficiency and intelligence.