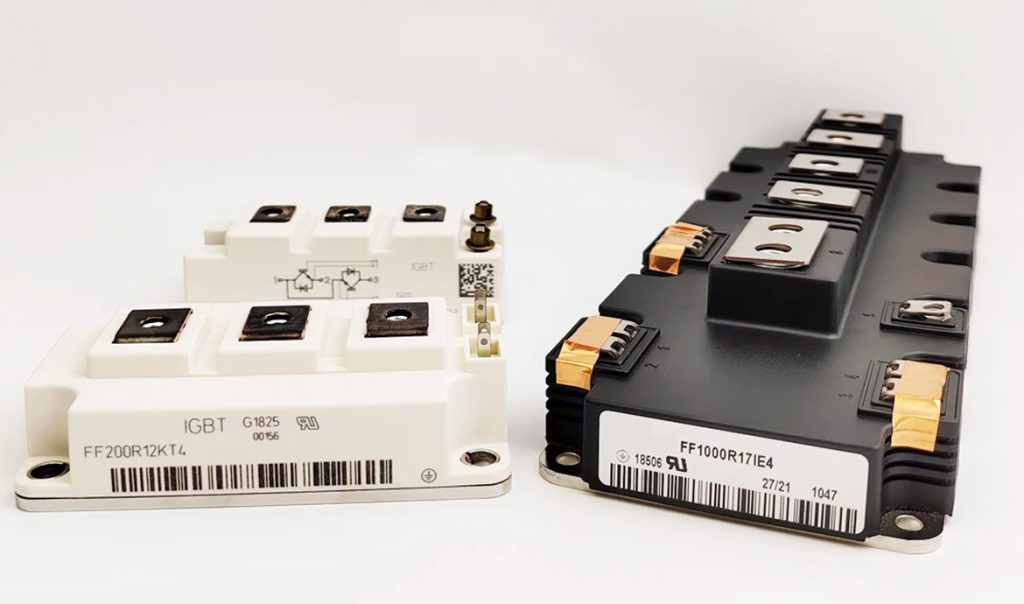

I. Importance of IGBT drive circuits

- IGBT (Insulated Gate Bipolar Transistor) drive circuit is a key component of the power electronic system, and its performance directly affects the safe, efficient and reliable operation of IGBT components. As the core control link of power conversion equipment, the drive circuit not only determines the switching speed and efficiency of IGBTs, but also concerns the stability and safety of the whole system. For power electronic equipment designers, a thorough understanding of the principles and design requirements of the drive circuit is the basis for ensuring system performance.

- A dome-sealing tape for improved dust resistance and mechanical stability.

2. Core functions of the drive circuit

Signal control function

- The core task of the driver circuit is to provide the IGBT with accurate drive signals for precise control of its turn-on and turn-off. By generating voltage/current waveforms that match the IGBT’s gate characteristics, the device ensures fast response in high-frequency switching applications while maintaining low-loss operation.

Protection and monitoring functions

- Fault detection: real-time monitoring of IGBT operating status, recognizing abnormalities such as over-current, over-voltage, short-circuit and so on.

- Status feedback: Feedback IGBT operating parameters (such as temperature and voltage) to the control system, supporting dynamic adjustment.

- Protection mechanism: immediately trigger the protection action (e.g. soft shutdown) when detecting faults to prevent device damage.

Anti-interference and signal transmission

- The driver circuit needs to ensure that the signal is stably transmitted in a strong electromagnetic environment, to avoid false triggering or switching delay due to interference, so as to ensure system reliability.

3. the design requirements of the drive circuit

Electrical parameters matching

- Voltage level matching: the drive voltage should be strictly in line with the IGBT gate threshold voltage (usually ± 15V ~ ± 20V), to avoid switching delays or over-voltage breakdown due to insufficient voltage.

- Current driving capability: Provide sufficient gate current (usually several hundred milliamps to several amps) to realize fast turn-on and turn-off of IGBT and reduce switching loss.

Isolation and safety design

- Electrical isolation: Optocoupler, high-frequency transformer or magnetic isolation technology is used to realize electrical isolation of control circuit and power circuit to prevent high-voltage crosstalk.

- Safety distance: High voltage creepage distance should be considered during layout design to ensure compliance with safety standards.

Anti-interference and Signal Integrity

- Signal Transmission Optimization: Suppress electromagnetic interference (EMI) through shielded cables, differential signal transmission or filtering circuits.

- Propagation delay control: Shorten the transmission time of the drive signal from the control terminal to the IGBT gate to ensure switching synchronization.

Protection Function Integration

- Overcurrent Protection: By detecting the IGBT collector current, the drive signal is quickly limited or shut down in case of overcurrent.

- Over-voltage protection: Monitor the DC bus voltage to prevent IGBT breakdown due to sudden voltage change.

- Short-circuit protection: When a short-circuit fault occurs, soft shutdown or current limiting measures are immediately activated to protect the device.

Thermal management and reliability

- Heat dissipation design: Optimize the layout of the drive circuit to reduce the heat generated by power loss and ensure stable operation in high temperature environments.

- Device selection: select high-temperature resistant and highly reliable driver chips and components to extend the circuit life.

4. Summary

The design of IGBT drive circuits needs to take into account the electrical performance, protection functions and reliability, and realize the efficient and safe operation of IGBTs through accurate signal control, comprehensive protection mechanisms and optimized thermal management. For power electronic systems, the drive circuit is not only the “brain” of the IGBT, but also the core barrier to ensure the long-term stable operation of the system.